The Role of Advanced Supply Chain Visibility: 3 Secrets from Industry Practitioners

Advanced supply chain visibility (SCV) is reshaping logistics, empowering businesses to navigate complexities with precision and efficiency. Traditional supply chain management, reliant on manual processes and isolated systems, often leaves enterprises blind to real-time developments. SCV bridges this gap by providing actionable insights, promoting proactive decision-making, and enhancing collaboration across networks.

The surge in digital transformation has made SCV not just a competitive advantage but a necessity. Technologies like IoT, blockchain, and predictive analytics are at the heart of this evolution, offering unprecedented transparency and agility. This article explores the core features, benefits, and secrets of SCV while addressing challenges and future trends, ensuring businesses can harness its full potential.

Why Supply Chain Visibility Matters in Modern Enterprises

The Growing Complexity of Supply Chains

Globalization and digital innovation have drastically complicated supply chains. Enterprises manage sprawling networks involving suppliers, distributors, and retailers across multiple geographies. SCV enables seamless coordination, ensuring real-time tracking of goods, compliance with regulations, and responsiveness to disruptions.

Impact on Customer Expectations and Business Performance

Today's customers expect faster deliveries, transparency, and personalized experiences. Advanced SCV meets these demands by ensuring timely updates and accurate delivery forecasts, directly influencing customer satisfaction and loyalty. Moreover, data-driven visibility enhances operational efficiency, reducing costs and boosting margins.

The importance of visibility extends to sustainability, with businesses leveraging SCV to monitor carbon footprints and achieve eco-friendly goals. This holistic impact makes visibility a cornerstone of modern enterprise success.

Key Features of Advanced Supply Chain Visibility Tools

Real-Time Data Analytics

Advanced SCV tools utilize real-time data analytics to provide instant updates on inventory, demand, and transportation. Companies can identify bottlenecks, optimize routes, and predict stock shortages with unmatched accuracy.

The Role of IoT and Edge Computing

IoT devices collect granular data from sensors embedded in vehicles, warehouses, and equipment. Edge computing processes this data closer to its source, reducing latency and enabling rapid decision-making. Together, these technologies revolutionize monitoring, ensuring SCV systems remain responsive and agile.

Enhancing Traceability with Blockchain

Blockchain ensures secure, immutable records of transactions across the supply chain. It fosters trust, enabling businesses to verify the authenticity of goods and improve compliance, especially in industries like pharmaceuticals and food.

3 Secrets to Successful Supply Chain Visibility from Industry Practitioners

Prioritizing Data Quality and Integration

Clean, centralized data is the backbone of SCV. Leading practitioners emphasize the importance of robust integration between Enterprise Resource Planning (ERP) systems and visibility platforms, ensuring consistent and reliable information flow.

Leveraging AI for Predictive Insights

AI-powered SCV tools excel at identifying patterns and predicting disruptions. By analyzing historical and real-time data, AI helps businesses anticipate demand spikes, optimize inventory levels, and prevent costly delays.

Collaboration Across Ecosystem Partners

Supply chains thrive on partnerships. Successful visibility depends on fostering trust and transparency across all stakeholders, including suppliers, logistics providers, and customers. Practitioners recommend adopting open data-sharing practices to enhance collaboration.

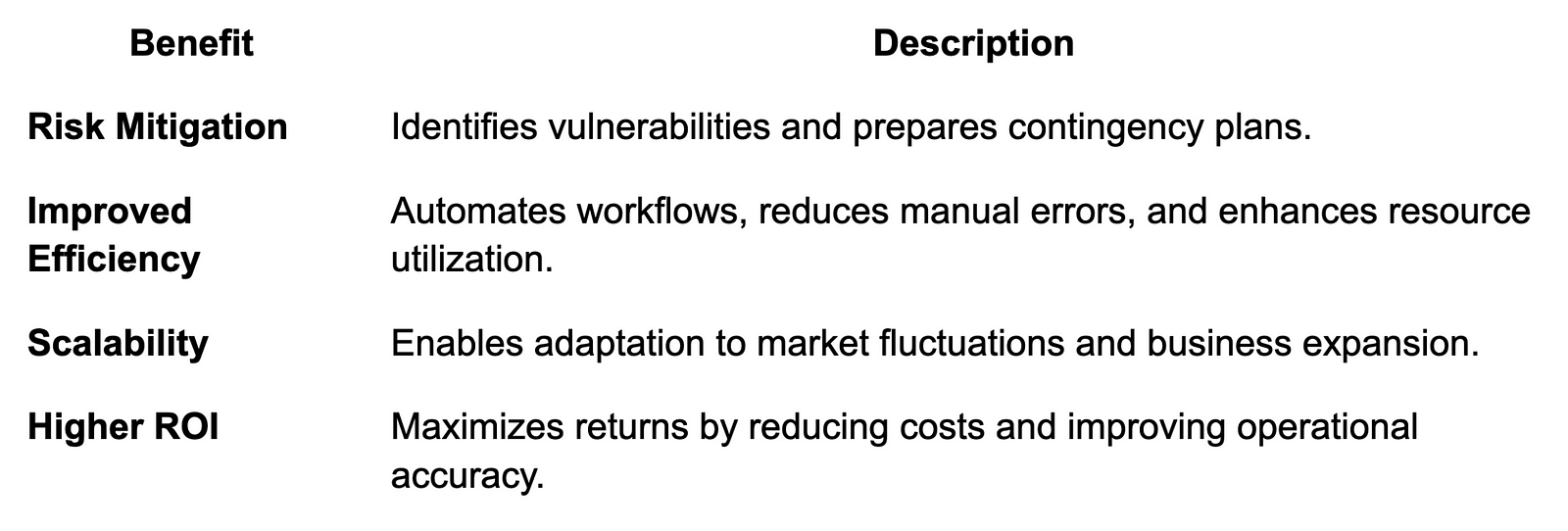

Benefits of Advanced Visibility in Supply-Chain Software Development

Supply chain software ensures these benefits are scalable and customizable, making them essential for achieving operational excellence. For tailored solutions, visit Trinetix Supply Chain Software Development Services.

Challenges in Implementing Advanced Supply Chain Visibility

Overcoming Resistance to Change

Cultural resistance is one of the biggest barriers to adopting visibility tools. Effective change management strategies, including training and clear communication, are essential to ease transitions.

Navigating Data Security Concerns

With SCV relying heavily on real-time data sharing, cybersecurity becomes critical. Businesses must implement robust encryption, access controls, and compliance frameworks to mitigate risks while ensuring data integrity.

Case Studies: Industry Leaders Leveraging Visibility for Success

Leading companies like Amazon and DHL have harnessed SCV technologies to redefine logistics. Amazon's predictive analytics optimizes inventory across its warehouses, ensuring minimal delivery delays. DHL's IoT-enabled tracking systems provide customers with real-time updates, setting new benchmarks for transparency.

These examples underscore how advanced SCV can revolutionize logistics, making businesses more efficient and customer-centric.

Future Trends in Supply Chain Visibility and Development

Embracing the Digital Twin Concept

Digital twins offer a real-time simulation of supply chains, enabling dynamic decision-making. By mirroring physical operations, businesses can test scenarios, optimize workflows, and foresee disruptions.

The Role of AI and Machine Learning in the Future

AI will further enhance SCV by automating processes like route optimization and demand forecasting. As machine learning algorithms evolve, they will refine predictive capabilities, driving cost savings and operational efficiency.

Conclusion: Embracing Visibility for a Competitive Edge

Advanced supply chain visibility is a transformative force in modern logistics. By adopting cutting-edge tools and practices, businesses can achieve unparalleled efficiency, customer satisfaction, and resilience. Embracing visibility today sets the foundation for long-term success, ensuring enterprises remain agile in a competitive marketplace.